Ultra High Speed Bearing Grease

SLR-77

Temperature Range: -20°F (-29°C) To 446°F (230°C)

Stable Viscosity At Ultra High RPMs | Will Not Form Carbon Deposits

Superior High Temperature Oxidation & Thermal Stability

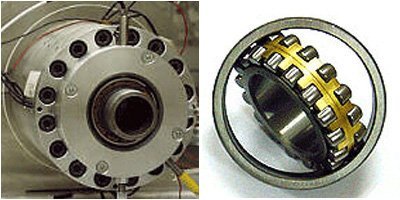

SLR-77 is a synthetic bearing grease that has been formulated for ultra high speed bearing applications. It has a wide application temperature range of -20°F (-29°C) to 446°F (230°C), allowing this multi-use grease to be available plant-wide for numerous applications at all bearing speeds. SLR-77 can cover the entire range of operations in most plants. It has been tested and field proven time and again to be one of the finest synthetic extreme speed bearing greases in the industry today. SLR-77 soars above the competition because it offers stable viscosity at ultra high RPMs and it won’t form carbon deposits. And, thanks to its superior high temperature oxidation and thermal stability, SLR-77 is a long lasting lubricant that can be counted on. SLR-77 is recommended for use in extreme speed bearing applications as well as most bearings associated with in-plant production equipment.

Recommended In:

- Extreme Speed Bearing Applications

- Most Bearings Associated With In-plant Production Equipment

As SLR-77 reduces the amount of friction present, the wear and tear otherwise caused to your equipment is reduced (which results in increased length of bearing life). Also, as the friction is reduced, less power is needed to maintain optimum performance and so less electricity is consumed. Furthermore, thanks to the synthetic base of this grease, it lasts longer than non-synthetic greases could. Due to its longevity of life, SLR-77 is able to reduce the frequency of required maintenance as it requires fewer and less frequent re-applications of lubricant. Less grease is consumed when lubrication intervals are prolonged and, when there is less down time, the cost of maintenance is lowered. Thus, it will serve to extend equipment life, increase lubrication intervals and minimize costly downtime – and this translates into a savings of time and money for you.

Extends Equipment Life | Prevents Downtime | Lowers Operating Costs

Reduces Friction and Wear | Multi-Use Lubrication

The lubrication protection provided by SLR-77 extreme speed bearing grease is truly superior. And, after you make the switch to SLR-77, there’s practically no longer a need to use multiple types of greases; SLR-77 is recommended for use in all speeds of greasing applications – plant-wide. Reducing the number of different lubricants in use is a method of streamlining that can save you even more time and money. Let SLR-77 help you reduce inventory, simplify maintenance, and eliminate the possibility of error caused by using multiple greases.

Available In 14 Oz Cartridges, 48 Lb Containers, & 120 Lb Containers

SLR-77 is available in three packaging sizes: 14 ounce cartridges, 48 pound containers, and 120 pound containers. It has a Timken Load rating of 36+ and a Four Ball Wear of 0.5mm. SLR-77 has a worked penetration of 265-295, a water washout rating of .9, and no dropping point. It is NGLI Grade 2 and offers an oxidation stability of -1. Protect your expensive equipment and reduce the cost and effort of running a production plant by applying SLR-77 premium extreme speed bearing grease today.

We at Superior welcome your questions and inquiries. Call us anytime toll free at 800-476-2072