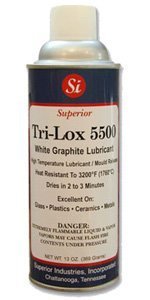

White Graphite Lubricant / Mould Release

Tri-Lox 5500

Operating Temperatures From -30°F ( -34.34°C) to 3,272°F (1,760°C)

This high temperature white graphite lubricant can be used in a variety of applications ranging from a mould release to a general purpose lubricant where a white dry lubricant is required. It is an excellent mould release agent for plastics, rubber, metal, and glass as well as many other applications requiring a dry high temperature graphite film. Tri-Lox 5500 is not affected by most gases, chemicals, acids and other harsh compounds found in most industrial environments. When looking for the best white graphite lubricant available, Tri-Lox 5500 should be your first choice.

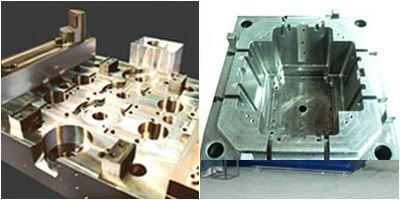

Tri-Lox 5500 White Graphite Lubricant Is Ideal for Many High-Temperature Mould Release Applications

Tri-Lox 5500 forms a non-wetting barrier preventing molten metals, rubber, glass, ceramic composites, and plastics from adhering to or reacting with moulds, dies, and other surfaces.

Excellent for Use In:

Molten Metal and Stamping Operations ♦ Rubber Manufacturing ♦ Plastics Manufacturing ♦ Glass Making Operations ♦ Ceramics Manufacturing ♦ High Temperature Casting, Extrusion, and Forging Operations ♦ As a Coating on Electrical Heating Elements

We highly recommend Tri-Lox 5500 for:

- Providing Cleaner Mould Release and Minimizing Surface Defects

- Increasing Mould/Die Life

- Reducing Defects and Increasing Processing Speed

- Insuring Cleaner Formed Shapes

- Maintaining Desired Electrical Properties

- Reducing Carbon Contamination Due to Graphite Plates

- Providing Easy Release After “Sintering”

- Providing Oxidation Resistance

- Reducing Surface Friction

- Railway Industry

High-Temperature White Graphite Lubricant Is Slick and Quick-Drying

Tri-Lox 5500 can be used in any application where a high-temperature, fast-drying lubricating compound is required. In addition to its excellent properties as a quick-release mould agent, Tri-Lox 5500 is also an outstanding extreme-pressure dry lubricant. Drying in less than two minutes, Tri-Lox 5500 is excellent at reducing friction and corrosion on aluminum, titanium, steel alloys, cast iron, brass, and copper, making it the lubricant of choice in a variety of high-temperature manufacturing and forging operations.

Using Our White Graphite Mould Release Reduces Production Costs

Tri-Lox 5500 reduces reruns of defective end products caused by adhesion and inefficient mould release. Remaining inert at extreme temperatures, Tri-Lox 5500 increases the life of die and molds by reducing surface friction, providing anti-oxidation barriers, and increasing resistance to corrosion. Its superb lubricity makes it ideal for reducing adhesion to even the most difficult shapes, improving mould release and shortening cycle times. A great electrical insulator and thermal conductor, Tri-Lox 5500 can be used on almost any surface. Its ability to reduce metal on metal friction makes it ideal for use on tracks, conveyors, oven parts, die-casting machines, and other high-temperature manufacturing operations. All of these benefits add up to less down time, less end product reruns, more efficiency, and more production savings.

Easy-to-Use White High-Temperature Graphite Lubricant

Tri-Lox 5500’s aerosol formula makes it easy to apply to even the most difficult to reach places. Each 13-ounce spray can covers approximately 28 sq. ft. of surface area. Tri-Lox 5500 is fast-drying, usually within one to two minutes.

We at Superior welcome your questions and inquiries. Call us anytime toll free at 800-476-2072