Injection Epoxy Crack Repair

Injection Pro 600

Injection Crack Repair For Structural Concrete

Injection Crack Repair For Structural Concrete

100% Solids • Moisture Insensitive

Injection Pro 600 is a two component epoxy injection adhesive for repair of non moving concrete structures. Formulations of Injection Pro 600 series range from extremely low viscosity, to materials that may be injected into concrete that is underwater, to very flexible, rubber-like compounds.

Recommended For Dry, Wet or Under Water Injection On:

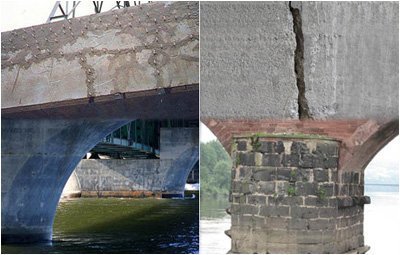

Precast Members • Retaining Walls • Piers • Pilings • Roads • Bridges • Beams & Columns • Concrete Block Support Walls • Reinforced Concrete Beams

Conveniently Packed In:

• 2 Component Dual Cartridges

• 2 and 3 gallon kits

• 10 and 15 gallon kits

Injection Pro 600 /100

General Purpose, low viscosity, high strength.

Injection Pro 600/101

LMF - Low modulus, very flexible.

Injection Pro 600/102

XLV - Extra low viscosity, high strength.

An epoxy adhesive for structural concrete, Injection Pro 600 Series is an epoxy crack welder and a two component epoxy adhesive designed for injection into non moving cracks in concrete. Formulations range from extremely low viscosity, to material that may be injected into concrete that is underwater, to very flexible, rubber-like compounds. As a moisture insensitive epoxy, Injection Pro 600 Series is totally insensitive to moisture and serves as an excellent epoxy adhesive for structural concrete. It isrecommended for all types of structural crack repair in concrete pilings, beams, columns, concrete pier supports, cross members, retaining walls and other concrete support structures.

Injection Ports Installed

Injection ports are placed in strategic locations to insure proper penetration. These ports will insure a thorough and satisfactory application by allowing Injection Pro 600 to reach all areas where crack bridging and repair is critical. Injection Pro 600 is applied by injecting with a two component positive displacement system or by using the dual component cartridges. Injection Pro 600 may also be hand mixed and poured manually into horizontal cracks. Mixing ratios for the epoxy injection crack repair product vary from 1:1 and 2:1 depending on which viscosity of Injection Pro 600 is used. There are three viscosities each designed for a specific type application Injection Pro 600 GP has exceptional tensile strength at 9500 psi. Injection Pro 600 LMF has extremely high elongation properties at 100% and very flexible. Injection Pro 600 XLV has extremely high strength and a lower viscosity. Injection Pro 600 is recommended for most of these type repair projects.

When injecting Injection Pro 600 Series, install epoxy injection crack repair ports at appropriate intervals to allow for compete penetration of cracks. Injection Pro 600 Series Epoxy crack repair is specially compounded from the highest grade materials and does not shrink. It is considered a 100% solids product, conforms to VOC regulations, and is the perfect epoxy adhesive for structural concrete.Epoxy crack welder Injection Pro 600 is recommended for structural crack repair and is used by engineering firms, bridge repair contractors and many other specialty contract engineering companies. If in question about the proper viscosity for a certain repair project or should you have a question concerning the proper applicator.

We at Superior welcome your questions and inquiries. Call us anytime toll free at 800-476-2072