Epoxy Line Marking System

Zone Guard 100

For Industrial & Commercial Concrete Floors

For Industrial & Commercial Concrete Floors

Lasts For Years

Available In Both White & Yellow

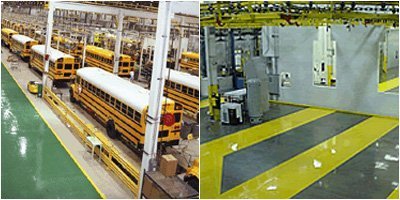

Zone Guard 100 is a two component epoxy that creates bold, permanent traffic lines on industrial and commercial concrete floors. This durable, high build epoxy resin floor coating creates very thick lines that outlast and outwear regular traffic lines. Zone Guard 100 is the high performance line paint of choice for identifying walkways and aisle ways, marking hazard zones and loading areas, and delineating crosswalks where forklift traffic occurs – just to name a few. This epoxy line marking system is recommended for use in production areas, warehouses, and tool rooms.

If permanency and durability are what you’re looking for in a line marking system, Zone Guard 100 is the clear choice. Epoxy paints, such as Zone Guard 100, are noted for their excellent bonding properties which enable them to go the distance and last for years longer than regular oil or acrylic paints. And because Zone Guard 100 is a 100% solids epoxy line marking system, it can be applied at any thickness.

Use for:

- Identifying Walkways & Aisle Ways

- CMarking Hazard Zones & Loading Areas

- Delineating Crosswalks Where Forklift Traffic Occurs

Each one gallon kit of Zone Guard 100 covers approximately 150 lineal feet (45.7 meters) at 4 inches (10 centimeters) wide and 25 millimeters thick. This epoxy line marking system can be applied by roller or brush, the recommended application form being a narrow short nap roller.

Use In: • Production Areas • Warehouses • Tool Rooms

Zone Guard 100 is available in both white and yellow and is packaged in a two part kit form. Part A is the clear liquid activator portion, which comes in a quart can weighing 8 pounds (3.6 kilograms). Part B is the pigmented liquid resin portion, which comes in a partially-filled gallon can weighing 12 pounds (5.4 kilograms). The Part B gallon container has extra room left in it so that the contents of the Part A quart container can be emptied fully into the gallon container, leaving sufficient room for mixing.

Instructions: Before applying this epoxy line marking system, test the concrete for moisture content. (Double priming or a special primer may be needed in areas where moisture exceeds 3.0 lbs./24 hours/1,000 sq. ft. using the calcium chloride moisture test.) Rid the application surface of all oil, dirt, and other debris. If detergents have been used to wash the surface, rinse the area with clean water to make sure there are no residual detergents. (This is because detergents can cause loss of bond as they act as parting agents.) Mechanically etch the application surface with a sander or wire brush and tape it off with a high quality masking tape. Double check that the edges of the tape that will be touching the paint are connected well to the application surface so the paint won’t seep under the tape (which would result in ragged edges on your lines). Because the activator and resin have a very short working time (if left undisturbed, a one gallon mixed unit of paint will harden in 20 minutes at 75°F, 24°C), make sure you are ready to use the product immediately upon the completion of the mixing. Part B (resin) should be stirred alone before Part A (activator) is mixed in so as to disperse any pigments which may have settled.

Empty all of Part A into Part B and mix completely using an electric drill and a jiffy-type mixing blade for three minutes. Apply the mixed paint to the prepared surface by using a roller or brush. The recommended application method is a narrow short nap roller as it can be done speedily. Float, rather than roll out, the paint. The pressure of the roller will determine the resulting thickness. Clean any mixing and application equipment immediately after using.

We at Superior welcome your questions and inquiries. Call us anytime toll free at 800-476-2072