30 Second Leak Repair

System-77

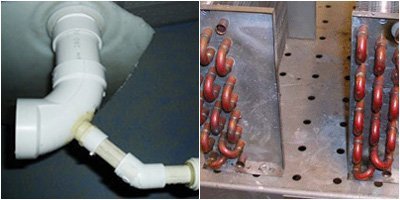

Copper | Brass | Steel | PVC | Fiberglass | Wood and more

Make Instant Repairs To Watercraft, Pipes, Concrete, Tubing…even under water

- 2 Unique Resins: SR 150, SR 250

- Cures In 30 Seconds

- Uses Special Blue S77 Curing Light

- Extreme Temperatures

- Underwater, Wet, Damp, or Dry Environments

System 77 Leak Repair is a cure-on-command resin product that works as a sealant, an adhesive, or a filler. This highly specialized instant pipe leak repair product can make repairs in circumstances most other repair products cannot, making it the resin of choice for use in harsh environments. System 77 Leak Repair is effectively used in underwater, wet, damp, or dry situations. This amazing quick cure product uses a unique curing mechanism that offers increased convenience: a particular wavelength of blue light. The special blue S77 Curing Light is able to cure the resin in as fast as 30 seconds. This photo-curable resin even cures that fast in extreme temperatures; these unique resins can cure equally fast at temperatures below 28°F (-2°C) and above 104°F (40°C), and when they do, their level of permanency and overall strength are not affected. System 77 Leak Repair is excellent for use as a sealant or filler on: brass, aluminum, stainless steel, copper, concrete, wood, polyethylene, PVC, ABS, FRP, HDPE, Gelcoat, and composite materials. It can also function as an adhesive for bonding disks, fiberglass mesh, or clear substrate hangers. (Note that when using System 77 Leak Repair as an adhesive, the top surface must be a clear substrate in order for the S77 Curing Light to reach the resin and ensure adhesion.)

Available In Kits (Which Include Both Products) Or As Individual Resins

System 77 Leak Repair offers three unique resin products that are optimized for various applications: SR 150 and SR 250. To best serve the needs of our customers, this premium leak repair system can be purchased as a kit (which includes one of each of these two great resins as well as a S77 Curing Light and accessories), or each resin can be purchased individually.

The special S77 Curing Light is also available in the Shopping Cart for separate purchase. Read on for more specifics!

Use For:

Underwater Repair • PVC Line Repair • Paddle Sport Repairs • Copper Water Line Repair • And More!

Use On:

Stainless Steel • Copper • Brass • Aluminum • Cast Iron • Lead Pipe • Black Pipe • Polyethylene • PVC • CPVC • ABS • FRP • HDPE • Gelcoat • PEX tubing • Polypropylene • Fiberglass • Wood • Concrete • Mesh Wraps

Thanks to its quick-curing formulation and its ultra convenient light-based curing mechanism, System 77 Leak Repair can be used almost anywhere – even in the most challenging situations and environments. This extremely versatile repair product is ideal for use on most marine materials as well as industrial product materials. This instant pipe leak repair can be used for so much more than fixing pipes – it can also be used for water craft repair and more! Water-sport related repairs are a breeze for System 77 Leak Repair; Boaters can use this instant leak repair during commercial or recreational marine outings. This fast curing resin is especially ideal for marine racing situations as it can be make a repair in a matter of seconds in the middle of a race. Take the System 77 Leak Repair Kit with you for emergency repairs to water craft, including sailboats, kayaks, and canoes.

Simple & Efficient | Cures On Command | Versatile | Layers Well

Repair | Seal | Adhere | Fill Cracks | Stop Leaks

Unlike typical epoxies which require the mixing of a resin and a hardener, these one-part resins don’t have to be mixed. Therefore, there are no complicated mix ratios or confusing application preparations. System 77 Leak Repair is a one-part product because it utilizes our unique high intensity blue S77 Curing Light. This visible light is not a UV light and is absolutely harmless. Thanks to its speedy curing time and few environmental considerations, System 77 Leak Repair can be used widely for machine repairs and can serve to minimize down-time due to maintenance.

System 77 Leak Repair resin can be used in deep fill applications as it bonds very strongly to itself and layers very well. It can be applied with Applicator Tabs, which serve to minimize waste and reduce the need for sanding after application.

No Harmful Side Effects From The S77 Curing Light

Applicator Tabs Minimize Waste & Reduce Need For Post-Sanding

Some Real Life Examples:

Fill Holes-

System 77 Leak Repair has been used on a New York City ferry that operates in the New York Harbor where low temperatures and salt water are concerns for other repair products. The specific repair using System 77 Leak Repair was done to fix ½ inch diameter holes in the steel housing of waterjet units. The resin cured in 1 minute and lasted as an excellent temporary solution for about a month’s time until the tail pipes could be replaced.

Stop Leaks-

System 77 Leak Repair has also been used in a lab at Barnard College in New York City to stop 6 leaks in a polypropylene RO piping system. Some of the leaks were able to be repaired without even shutting off the water! The wet surfaces were not a hindrance for System 77 Leak Repair. Although it took a little extra time to cure where the water was still flowing, the repairs were all able to be done successfully and economically.

Fix Sailboats-

System 77 Leak Repair has been used in multiple applications by members of a “dry sailing” racing team on their J-24 Sailboat in Ithaca, NY. They applied layers of resin along with fiberglass mesh to the trailing edge of the keel in order to rebuild a chipped area. The resin was also added to a blistered area in the gelcoat on the underside of the boat, as well as to a cracked area in the gelcoat on the keel stub, forming a layer of necessary protection. Furthermore, the boaters used System 77 Leak Repair products to fill a deep gouge in the hull. The specifications of this instant leak repair resin were exactly what was needed for this team to make quick fixes and get back to the joy of racing.

There are two types of resins available in the System 77 Leak Repair series:

SR150 and SR 250. These two resins vary in their suitability for different applications. For example, one is best suited for metals but weaker on plastics, and another is best suited for plastics and less suited for metals. To assist you in making the best choice for your application needs, we’ve created the chart below. Also, be sure to check out our Tech Data sheet for thorough technical information for each resin type.

| Applications | Good | Better | Best |

| Metals* | SR 150 | SR 250 | SR 250 |

| Plastics** (Including Fiberglass) | SR 250 | SR 250 | SR 150 |

| Wood | SR 250 | SR 150 | |

| Concrete | SR 250 | SR 150 | |

| Rubber | N/A | N/A | N/A |

| Vertical & Horizontal Filler | SR 150 & SR 250 | SR 250 | |

| Pin-hole, Crack, Joint, Elbow, Pipe & Tank Repair | SR 150 & SR 250 Are Preferred | ||

| Low Pressure Applications, Filler | SR 150 & SR 250 | SR 250 | |

| Use With Mesh Wraps For Reinforcement | SR 150 & SR 250 |

*”Metals” Include: stainless steel, copper, brass, aluminum, cast iron, lead pipe, and black pipe

**“Plastics” include: PVC, CPVC, ABS, FRP, HDPE, PEX tubing, polypropylene, and fiberglass

Now that you’ve seen the chart above, here’s a rundown of the highlights of each resin. (Note that just because these are the categories that each resin specifically performs best in, they may do well in the other categories. Reference the chart for specifics of how each resin works in regards to various application surfaces.) SR 150 is formulated for optimal adhesion to Gelcoat, polyethylene, FRP, PVC, CPVC, concrete, and wood. It is a high viscosity material that will not run when applied in vertical applications. It can fill holes and cracks and can be used for sealing, encapsulating, and coating. When applied properly, SR 150 can be machined. SR 250 is formulated for optimal adhesion to brass, copper, steel, bronze, cast iron, and aluminum. Like SR 150, this high viscosity material won’t run when applied vertically. Use SR 250 to fill holes and cracks and to seal, encapsulate, and coat. When applied properly, SR 250 can be machined. SR 250 is formulated for optimal adhesion to plastics, metals, composites, wood, and concrete. This resin has the consistency of a paste and cane be applied in vertical applications without running. It can fill voids, defects, or cracks and can be used to create conduit end-caps. When properly cured, SR 250 can be sanded and painted.

Available In Kits Or As Individual Resin Tubes System 77 Leak Repair Offers: SR 150 & SR 250

System 77 Leak Repair is available in kits or as individual resin tubes. The kit consists of 1 tube of each System 77 Leak Repair resin (3 total), 1 blue S77 Curing Light, mesh for reinforcing, and abrasive sand paper for creating the proper texture to insure proper adhesion. Resin tubes are also sold individually. The blue S77 Curing Light can also be purchased separately in the Shopping Cart. System 77 Leak Repair is solvent-free. SR 150 and SR 250 are safe for potable water according to Underwriters Laboratories Inc. in accordance wit ANSI/NSF Standard 61. Note that System 77 Leak Repair is not intended for use on rubber surfaces. Also note that exact cure times of this instant pipe leak repair will vary given the variables of application depth and resin type.

We at Superior welcome your questions and inquiries. Call us anytime toll free at 800-476-2072